Acrylic

Acrylic or Plexiglass has mass usage and popularity in sign projects. Acrylic can be used both indoors and outdoors pushing your signage to another level. Acrylic Printing provides vivid colors and graphics to best suit your business.

Acrylic is a durable plastic material also known as Plexiglas. This material is a glass substitute, but it is more durable than glass. Below find more information about the types and specifications of the Acrylic material.

Acrylic is considered to be one of the most rigid types of plastic. Even though it has many similarities in appearance with glass, it is way more durable. It can withstand harsh winds and rains. So whenever you need a Sign made of a rigid material you can consider Acrylic.

Acrylic is a thermoplastic which means that under hot temperature it can get soft. This helps to give this material any shape and mold it in any desired way. You can get Acrylic in any form, as this material is very easy to shape.

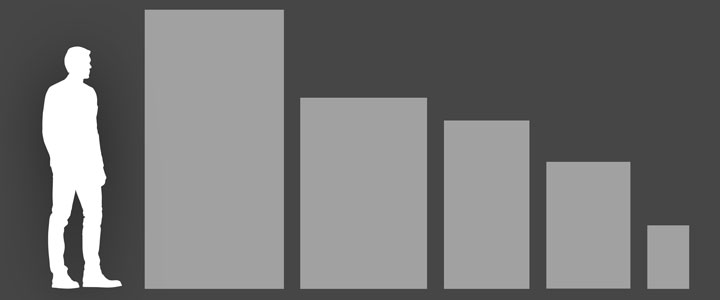

As for the thickness, it can be 1/8"/0.125"- 0.750lbs/sqft, 3/16"/0.188"-1.200lbs/sqft, 1/4"/0.25"-1.500lbs/sqft, 1/2"/0.5"-3.000lbs/sqft

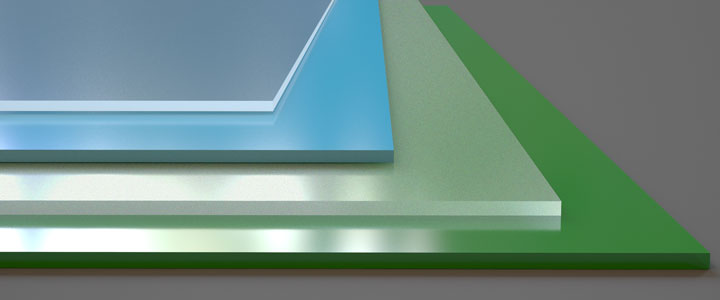

The Acrylic material has 4 types: Clear, Colored, Frosted and Translucent. Clear Acrylic looks Similar to glass, as it does not have any color and is fully transparent. But it is more shatterproof and flexible than glass. Clear Acrylic provides light transmission for 92%. Colored Acrylic can be in many color. You can get Acrylic varying from lighter shades to darker shades. Colored Acrylic is perfect for making Illuminated Signs. Frosted Acrylic comes in light grey - etched glass finish. Frosted gives an elegant look to the material. Translucent Acrylic lets light pass through it but it is not completely transparent. Translucent Acrylic also comes in any color.

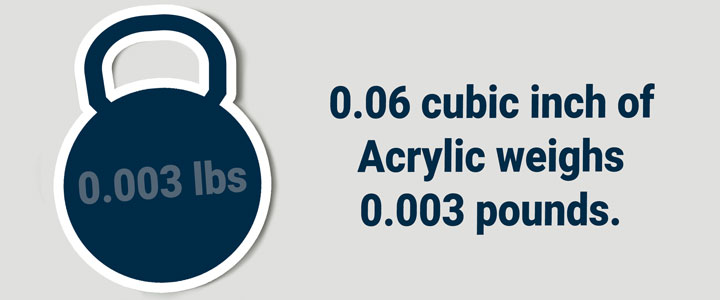

Acrylic is known to weigh more than most other Plastic types but it weighs less than glass. 0.06 cubic inch of Acrylic weighs 0.003 pounds.

The size of the Acrylic sheet is fixed but we can make Signs in custom sizes.

Acrylic plastic is often used in the sign making industry due to its durability which makes it withstand any weather conditions. Therefore, it can be used not only indoors but outdoors as well.

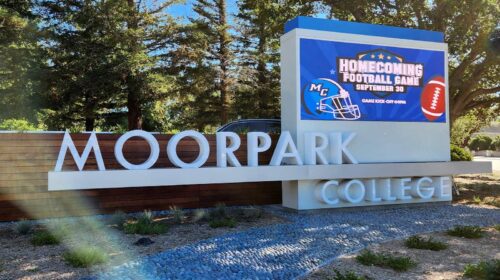

Acrylic can be used to make Lightbox Signs. This material lets light pass through it and that is the exact, which comes handy for a Lightbox fabrication. Besides, Illuminated Cabinets are often displayed outdoors and as it is a weather resistant material, it will not get damaged. Channel Letters also require Acrylic for their construction, again for the same reason, to let light pass through it. These are type of illuminated letters that can be custom-made with various Acrylic colors. Pylon Signs can be made of various materials and one of them is Acrylic. These are tall freestanding signs that can often be found next to malls, business centers and highways. Acrylic is used to make the face part of the Plaza Sign which can either be illuminated from inside or not. We can use direct printing or Vinyl letterings to depict any information on the Acrylic.

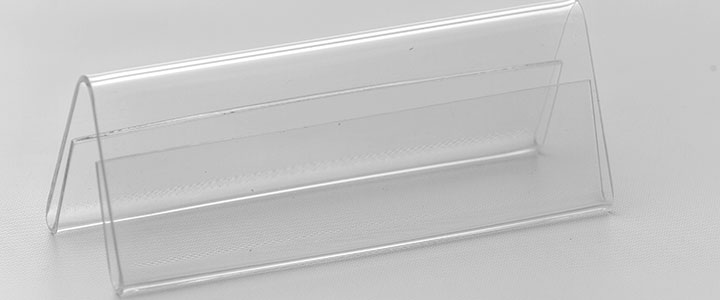

Interior Signs can be of various purposes, ranging from corporate, industrial to decorative. For making these signs any material can be used and Acrylic is among those materials. With Acrylic, we can make interior door name Signs, office table top stands, brand logo Signs, Hanging Signs and many more. Acrylic can be used to make all types of Decorative Signs as well. Acrylic material is used to make Interior Signs for offices, hotels, homes and for many other premises.

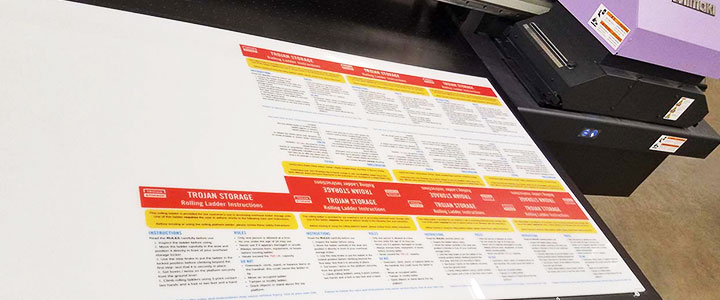

For printing on Acrylic, we use high-quality UV inks. The printers are UV curing, which means the ink is dried in the process of printing. This makes the ink sun resistant. The print on this material will last for a long time without losing its vivid colors.

We use a very accurate CNC Miller for cutting an Acrylic sheet. These machines give matt edges to the Acrylic. For cutting Acrylic, we can use a Laser Cutter as well which gives a glossy finish to the edges. With these machines we are able to give any shape to the Acrylic material.

Our newest acquisition - Matthews painting machine with the color range up to 80.000 different shades including metallic colors with satin and gloss finishes, can custom paint the material in your desired shade and finish with ease.

For Engraving, we use again CNC Router and Laser cutting machines. All the machines offer neat finishes. So, you can order Acrylic Signs with any graphics or information engraved on them.

Enter your details and attach your project files if you have any. Our agent will get in touch with you shortly to provide a free quote and consultation for your project.

Please note that Front Signs is a full-cycle sign making company. We tailor each case to match your vision, starting with design and fabrication then finishing off with permitting and installation. No matter how simple or sophisticated your concept, we’ll bring it to life with quality and precision.