We received your message and we'll contact you as soon as possible.

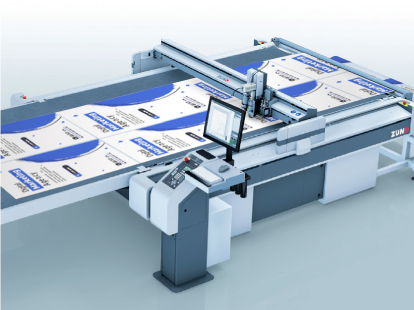

A computer-controlled technology that cuts through firm and soft materials. The machine trims with extreme precision, providing a matte finish to edges.

The method provides surface-level carvings to materials based on specifications. It uses a series of router bits to inscribe detailed patterns on hard and soft materials.

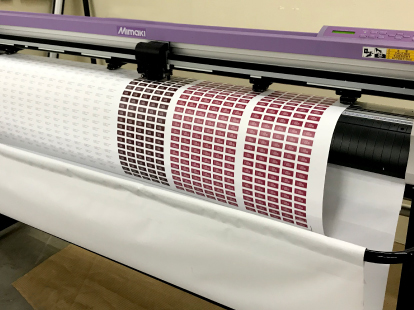

A fast and efficient process for cutting through sturdy but thin materials. The tool lets us trim several designs across the same sheet, optimizing production time and effort.

The technology uses a beam of light to cut materials of varying sizes and textures. It produces displays featuring complex designs with minimal material loss.

The technology uses a beam of light to cut materials of varying sizes and textures. It produces displays featuring complex designs with minimal material loss.

A product trimming technique ideal for thin and soft materials such as adhesives. The machine uses different knives, giving a distinct finish to each project.

Let us bring your vision to life. We create bespoke commercial displays to level up your brand. Our professional sign making company specializes in cutting and engraving materials to suit your style and objectives.

Cutting and engraving are among the top sign services that we offer, developed over many years of experience. We use the latest technologies to create distinctive business signs with refined details

Enter your details and attach your project files if you have any. Our agent will get in touch with you shortly to provide a free quote and consultation for your project.

Please note that Front Signs is a full-cycle sign making company. We tailor each case to match your vision, starting with design and fabrication then finishing off with permitting and installation. No matter how simple or sophisticated your concept, we’ll bring it to life with quality and precision.